Booze on the plane? Not if it powers the engines

LanzaJet becomes the first company to receive funding from the Bill Gates-backed Breakthrough Energy Catalyst project, to bring the world’s first alcohol-to-jet fuel production plant online.

The quest for green jet fuel

LanzaJet, an Illinois-headquartered technology company is one step closer to decarbonizing air travel as it becomes the first company to receive funding from the Bill Gates-backed Breakthrough Energy Catalyst project. Bringing together businesses and nonprofits to fund first-of-its-kind commercial scale projects, the $50 million award will help LanzaJet to bring the world’s first alcohol-to-jet fuel production plant online at Freedom Pines in Georgia, USA.

Bypassing the ‘Green Premium’

With around 2-3% of the world’s greenhouse gas emissions coming from the aviation industry, the use of sustainable aviation fuels (SAFs) is important for protecting the environment. But bringing any new product, especially a world first, to the market is difficult and costly. Green projects struggle to raise capital because they often run into unexpected costs or challenges, which makes investors wary. The $50 million Catalyst grant awarded by Breakthrough Energy is designed to speed up the deployment of clean technologies through funding early commercial facilities like these. Breakthrough Energy is a $1 billion fund from a group of organizations that includes General Motors and the Boston Consulting Group.

The rest of the money needed to bring the Freedom Pines SAF plant online comes from earlier supporters of LanzaJet’s work, such as Mitsui & Co., Suncor Energy, British Airways, and Shell. Once up and running, the Georgia plant will produce 9 million gallons of fuel, though this is only a small fraction of the 14 billion gallons of aviation fuel consumed by the USA each year.

Turning booze into jet fuel

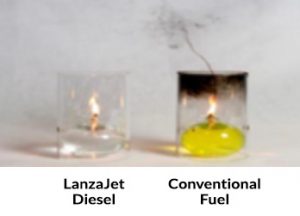

Sustainable aviation fuel, one of several technologies positioned to reduce the greenhouse gas impact of aviation, is a wide label given to fuel that is made from sources other than kerosene. LanzaJet’s technology takes ethanol (alcohol) from Brazilian sugarcane sources or US corn sources, and chemically converts it into jet fuel and diesel.

Depending on the feedstock used to make the ethanol, greenhouse gas emissions from LanzaJet’s fuel would be at least 70% lower than conventional fuel. The burning of the alcohol-derived SAF still produces the same emissions as regular jet fuel, however, because the feed stock absorbs carbon dioxide from the atmosphere as it grows, the total calculated emissions are lower. LanzaJet hopes to create fuel that produces as much as 85% less greenhouse emissions than fossil fuel derived jet fuel by switching to second-generation ethanol, including ethanol made from non-edible food crop byproducts and waste biomass. Because the fuel produced through the process is chemically identical to kerosene-based fuel, SAFs can simply be ‘dropped in’ as a replacement fuel without needing special engine conversions.

The technology itself is far from new, but since its development nearly a century ago, it has been refined to work at higher efficiencies and lower costs. Despite this, SAFs are still extremely energy intensive to create. Without subsidies or incentives, the cost of LanzaJet’s sustainable aviation fuel would be nearly twice the price of traditional kerosene-based fuel, a hurdle the company will have to overcome if it is to be commercially viable.

Going global with Project Speedbird

LanzaJet is already preparing for a large market share. In 2021, they teamed up with Nova Pangaea Technologies to provide a feasibility assessment for British Airways about using SAF in the UK, known as project speedbird. This project has now moved into the next phase: the development of a production site in the North-East of the UK to supply 102 million liters of SAF per year. As Jimmy Samartzis, CEO of LanzaJet said, “the UK is a critical market in decarbonization of the aviation industry, and this partnership brings together the full value chain from the agricultural and wood waste, to finished sustainable aviation fuel in-use by British Airways.”

Sources: lanzajet.com – techcrunch.com

There are no comments

Add yours